Buffing and polishing metals, stone, glass and wood is easily done with the aid of a rotary tool and various buffs, wheels, mops, bobs, pastes and compounds.

However, sometimes you need some control over the material you are polishing and you may need to be careful where the polisher or abrasive is applied to prevent further scratching, marking or polishing.

It may be that you want a desired finish on one section of the work and not another, or perhaps the piece you are polishing requires some specifically shaped polishing tool and therefore you need to cut and make your own tools.

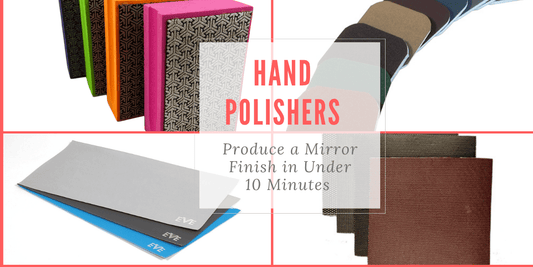

The following polishers are to be used on metals, glass, stone, ceramics, hard woods, enamels and plastics to achieve a mirror finish shine in under 10 minutes.

Each hand polisher as the name suggests can be used by hand without the need for a machine or rotary tool, and each one can be cut, flexed and manipulated to be applied to your work whatever the size or shape.

#1. Diamond Polishing Cloths

Diamond grit has been used as an abrasive for a long time for polishing hard materials but usually the diamond abrasive is attached to a fixed object such as a diamond burr or a diamond file.

This isn't always convenient when you want to be able to polish in awkward areas or make your own diamond tools with much finer diamond grit.

With these cloths you get the cutting power of a diamond but on tough and flexible fabric cloth. Each cloth is impregnated with very fine diamond abrasive and they are wonderfully adaptable and easy to use.

Diamond is the hardest natural material so these cloths are much tougher and longer lasting than aluminium oxide paper, sanding paper or emery paper. This also means you can use them on just about any other hard material.

Great for polishing items such as:

- Cabochons

- Gemstones

- Glass

- Quartz

- Sapphire

- All hard metals

- Granite

- Marble

- All hard woods such as Ebony and Pink Ivory

You can use the cloths as they are or cut them to any shape you like and stick them to mounts, mandrels, sticks and objects to make your own tools.

Use them as you would sandpaper or any other abrasive. Why not try making some homemade buff or emery sticks? Cut or find some wood in the desired shape, wrap the diamond cloth around and secure it with glue, tape or staples.

The set comes with three cloths, each one measuring 140mm x 75mm (roughly 3" x 6") In each set you get three different very fine grades of cloth:

- 2,400 grit - Black, equivalent to 10 micron

- 4,000 grit - Blue, equivalent to 5 micron

- 12,000 grit - Grey, equivalent to 2 micron

These particular diamond polishing cloths are made by EVE, Ernst Vetter, in Germany.

"If you need to sand, smooth and round off a piece of glass you've cut, but the glass is a funny shape then these diamond impregnated fabric sheets will reach into the most awkward places. You can just wrap them around a shaped piece of wood, or your finger" - Rob Page.Guild of Glass Engravers

"Beneficial for very close grain woods such as Ebony and Pink Ivory where you have a very close grain and want to achieve a glassy look to your finish" - Jason Townsend. The Woodcarvers Gazette

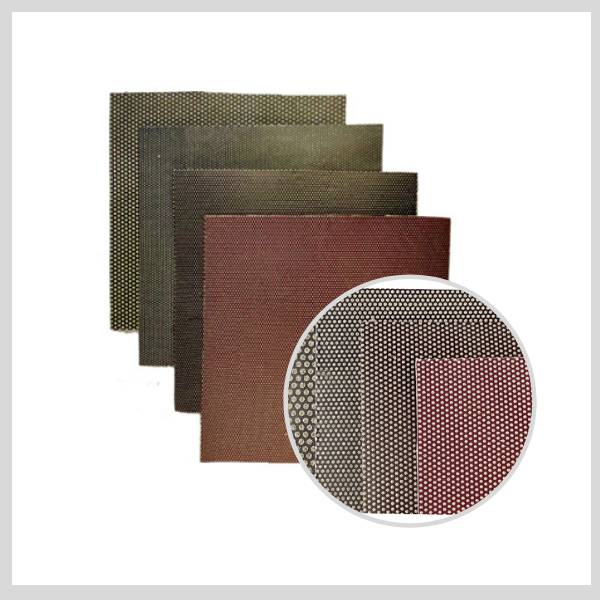

#2. Diamond Abrasive Flexible Sheet

Not so much a polisher, but more of a flexible grinding sheet. They are worth mentioning in this hand polishing article because if you like using the above diamond polishing cloths we spoke about, then these flexible sheets act as a great pre-polisher to the cloths.

They range from anything between 60 grit to 2000 grit which is still a fine grade of diamond grit, but coarser than the diamond polishing cloths. They are brilliant for removing any unwanted marks and snags on your work before moving on to using either the cloths, diamond compound for polishing or another polisher.

They measure 100mm x 100mm (4" x 4"), are 0.3mm thick and the sheet is bendy and foldable. Cut the sheet into your desired shape and size, and stick the abrasive to whatever you fancy making your own grinding, shaping, deburring, polishing and sharpening tools.

#3. Micro Mesh Soft Touch Sanding Pads

To try and explain how Micro Mesh differs from other abrasives let's use polishing metals as an example. If you are using an abrasive emery stick you quite often find you have to repeatedly buff backwards and forwards to try and achieve a smooth finish.

With each stroke, you can often create more marks and scratches instead of removing them because the backing to the abrasive is solid and unforgiving.

With Micro Mesh pads the cushioned foam backing allows a little more give, and subtlety. You can produce a really nice satin finish faster and more evenly than with conventional papers, and without you having to continuously cover your tracks all the time by polishing over what you've already polished in order to try and remove scratches.

Without wanting to get too technical, the abrasive crystals in these pads are larger than in conventional paper abrasives so they last longer and do not clog so easily. You will get better, and quicker results without so much elbow grease.

Used by:

- Polymer clay bead jewellers

- Wood turners and carvers

- Pen turners

- A Luthier. Musical instrument makers.

- Furniture restorers

- Model makers

- For small projects on wood, acrylics, resin, paint, plastics, most metals and polymer clay

Can be used wet or dry but to preserve the life of the pad, use wet with little pressure and dry off thoroughly after use. This particular set contains a full range of nine different grades from coarse to medium to fine and ultra-fine so you can start on a piece and take it right through to a final finish.

The pads are approximately two inches square and double-sided with rounded corners.

The kit contains a reference card and one square of each of the following grits, along with a grit conversion to show the equivalent diamond grit in microns:

- 1500 grit, equivalent to 30 microns

- 1800 grit, equivalent to 15 microns

- 2400 grit, equivalent to 13 microns

- 3200 grit, equivalent to 9 microns

- 3600 grit, equivalent to 8 microns

- 4000 grit, equivalent to 5 microns

- 6000 grit, equivalent to 4 microns

- 8000 grit, equivalent to 3 microns

- 12000 grit, equivalent to 3-2 microns

"I really like these little pads and the fact that they are double sided is great. Wood turners would enjoy using these pads to polish. They're ideal to hold against a spinning cylindrical form. They have a place with the wood carver as well, I have two carvings that easily benefit from these pads; one a Tagua nut carving and a Whitby jet carving. You can really apply a high polish with these and I would definitely recommend them" - Jason Townsend. The Woodcarvers Gazette

"Pleased with the micro mesh pads, very practical, full range from coarse to very fine mesh. Haven't yet tried the pads on plastics, but I have heard from other users that these micro mesh pads are the solution to obtain a satisfactory gloss on those materials which are so difficult to polish"

"You can get a nice satin finish on silver a lot faster and a lot more even than with conventional papers.They're flexible which is really useful for flat and curved shapes, you've got the edges and the corners too, and when they do get dirty you just flip it over and you've got the other side as well. A really, really great set and I highly recommend them" - Dave Wilson. Celtic Dreams

#4. Diamond Hand Pads

This may sound obvious, but these are called hand pads because they comfortably fit in your hand making them easy to hold and easy to work with. Because of their flexibility, they work well on polishing curved edges or dome shapes.

They come in a variety of grit sizes:

- 50 grit very coarse (only available in diamond lapidary hand pads)

- 60 grit very coarse 100 grit coarse-medium (only available in diamond lapidary hand pads)

- 120 grit coarse-medium

- 200 grit medium

- 400 grit medium-fine

- 800 grit is very fine (only available in diamond resin hand pads, see below)

- 3000 grit super fine (only available in diamond resin hand pads, see below)

They can be used wet or dry on glass, ceramic, carbide and stone and are particularly great for use on cold working glass projects to remove snags and smooth off edges. They work wonders for removing kiln wash and to either roughen or polish glass or ceramic surfaces, smooth fused glass edges, smooth stones, granite and rock.

With a multitude of uses, these pads are great to have around in different grit sizes to fulfil all your jobs.

Here are some of the handy things you can do with yours:

- Remove batt wash/kiln wash from glass and ceramic

- Remove snags and rough edges from carbide, fused glass and cold-working glass projects

- Roughen ceramic, glass or glazed pottery surfaces for preparation in mosaic work

- Wet grinding work on all glass, stone, ceramic, shell and bone

- Smoothing and shaping carbide, large stone/granite or marble workpieces

- Restoration of Carrara marble tiles

- Smoothing of concrete countertops

"I bought the diamond hand pads and I will never regret it. The glaze over ran the vase I made and the base was covered in excess glaze and needed removing. The hand pads worked; my vase is intact and now has been sold" - Raymond Gilbert-Griffiths

"Ever tried to get rid of the ridiculously sharp edge you make when you cut a sheet of glass? What you need to do is to sand it smooth and round off the sharp edges. By far the best tool for this job is a diamond sanding pad from Eternal Tools. They have various grades so that you can quickly get to as smooth a finish as you need" - Rob Page. Guild of Glass Engravers

#5. 3-in-1 Abrasive Buff stick

A super handy tool to have around is this quick and easy-to-use 3-in-1 buff stick. 3 grades of abrasive grit on one stick to pre-polish, polish and buff. Take a look at the short video on the product page to see how to buff up a shine in seconds!

#6. Diamond Polishing Paste and Dialux Polishing Compounds

Not hand polishers as such, but diamond paste and Dialux Polishing compounds deserve to have a rightful place in this article because they can be applied to anything and used by hand to polish a whole myriad of materials.

Diamond Polishing Paste

Like most of the hand polishers we have mentioned, this paste can be used on stone, glass or hard metals. Available in fine to coarse grades, you can take a relatively coarse and grained looking piece of metal, stone or glass work down to a superb mirror finish in no time.

The diamond grinding paste is mixed with a water soluble oil and comes in an easy-to-apply 5g syringe, so the paste is ready to use and is easy to apply.

They are graded in microns rather than diamond grit and can be bought in the following micron sizes. Also shown is a rough conversion chart from micron to grit.

- 0.25 micron = 60,000 grit

- 1 micron = 14,000 grit

- 3 micron = 12,000 grit

- 6 micron = 6,000 grit

- 8 micron = 3,000 grit

- 14 micron = 1,200 grit

- 25 micron = 800 grit

- 45 micron = 325 grit

- 90 micron = 140 grit

- 0.25 - 3 micron for final polishing

- 6 - 14 micron for lapping and pre-polishing

- 25 - 90 micron for rapid stock removal

HELPFUL TIP: Apply with a piece of wood such as a peg or toothpick (for very detailed work), a piece of leather or flexible plastic or one of our felt polishing bobs. The finer grades of paste will absorb into wool, felt or material so be sure to apply these with wood, leather or plastic.

Many scientists use the 0.25 micron to give a microscopic ultra smooth finish. Ideal for removing scratches on a watch glass, glass or gemstones. Try starting with 6 microns (yellow), then 3 micron (green) and so on until the desired finish is achieved.

For glass engraving, use the diamond paste for the final stages of polishing, applying a tiny amount to a felt bob or point.

On this note, if you have a plastic watch glass you will need to use Polywatch. Polywatch is a very light abrasive used for removing scratches from plastic watch glasses. It comes in a handy size tube and can be applied with a bit of cotton wool.

How to use our Diamond Polishing Paste

Most diamond paste grinding and polishing is done progressively, starting with the coarser grade, 6 microns, and then finishing with the 1 or quarter micron grade. If the work you are polishing is already of a reasonable finish then you can often skip the coarser grades and start with the 3 or 1 micron.

To apply the paste you can either use a felt polishing bob on a rotary tool, a piece of leather or wood or if polishing a pivot then apply the paste directly and then use a wooden peg to grind with. Alternatively apply to a soft wheel using a canvas belt, one belt for each grade. There are so many ways to apply the paste it seems that everyone has their own method, I have even heard of one horologist using some old camera film!

"Great, grinding paste, removes fine scratches from crystal glass with a little bit of elbow grease or a Dremel. Have also removed scratches from sunglasses, worked really well""For a wee scratch on a hard stone, this paste did an excellent job; not too pricey either"

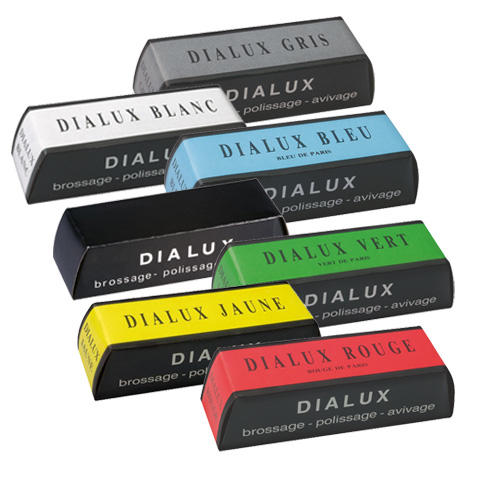

Dialux Polishing Compounds

The Dialux range of polishing compounds (sometimes referred to as Rouge and Tripoli) really is the Rolls Royce of compounds for polishing metals.

The compound is uniformly blended with abrasive grit so only a small amount needs to be applied to a felt bob or wheel with minimum clean up required.

- Dialux Blanc/White - Silver, White Gold & Plastics. High lustre finish

- Dialux Bleu/Blue - Gold & Silver. Removal of scratches, cleaning and a high lustre finish

- Dialux Rouge/Red - Gold & Silver. High mirror finish

- Dialux Vert/Green - Platinum, Stainless Steel & other hard white metals. Final polishing process

- Dialux Gris/Grey - Stainless Steel & Platinum. Removal of marks and finishing

- Dialux Jaune/Yellow - Non-ferrous metals (eg. Bronze and Tin) & Plastics. Removal of scratches and pre-polish

- Dialux Black - Argentium Silver. Mirror finish

#7. Diamantine Powder

Diamantine is a very fine powder used primarily by watchmakers to produce a mirror finish, scratch free on hardened steel pivots and jewels. You mix the powder with a tiny bit of oil to form a thick putty-like paste. For further help on using Diamantine have a read of the late George Daniels book 'Watchmaking'.